[print_link]

Well the chairs are complete along with other household projects, and now I’m back to fly rods. It seemed like I painted forever. Thirty-nine parts per chair got two coats of paint on all sides and then the assembled chair received a third. I can tell you how to clean a brush and modify latex paint so that it will dry slower and streak less, but that’s a different story.

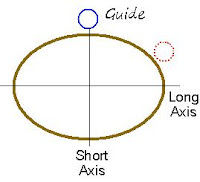

The whole thing about  rod spline is about deciding what side of the blank to place the guides on. If you think of the cross section of a rod, fiberglass or graphite, being oval shaped instead of round, you can visualize what happens when it is bent. The rod will want to bend in the direction of the Short Axis. Place the guides on the Long Axis and the rod will be unstable. It will insist on bending to one side or the other toward the Short Axis. The same is true if the guides are located off axis like the dotted red guide. Guides not on or opposite the spline will cause a twisting stress in the rod and a wave in the line as the rod vibrates during the cast. The wave will decrease your accuracy and distance.

rod spline is about deciding what side of the blank to place the guides on. If you think of the cross section of a rod, fiberglass or graphite, being oval shaped instead of round, you can visualize what happens when it is bent. The rod will want to bend in the direction of the Short Axis. Place the guides on the Long Axis and the rod will be unstable. It will insist on bending to one side or the other toward the Short Axis. The same is true if the guides are located off axis like the dotted red guide. Guides not on or opposite the spline will cause a twisting stress in the rod and a wave in the line as the rod vibrates during the cast. The wave will decrease your accuracy and distance.

Finding the spline is easy. Place the butt end of a section on a hard surface and support the tip end with one hand while pressing in the center to cause a bend. Now by rolling the rod you will cause it to snap to its comfortable position, as if the flat side of the oval were on the surface. Likely you will find another comfortable position opposite the first. One may feel more significant than the other. Mark the upward side of the rod section. This is the inside of the curve. The Spline is commonly said to be the bottom side or outside of the curve.

I marked my rod blank before cutting it. After the ferrules were installed I checked each section and the assembled blank. I’m checking the assembled middle and tip section in the picture. In all cases the spline was still where marked.

The guides will be located in line with the mark and as indicated in the diagram. By the way, I can’t measure with a dial indicator that my blank is more than 1% of its diameter out of round. Spline is easy to visualize as the result of your rod being oval, but it is really the sum of manufacturing characteristics that cause it to bend one direction more easily than any other. There are arguments for placing guides on the spline side and opposite. They involve having the greatest bending resistance when casting forward or pulling backward (fighting a fish). I don’t believe it matters, and it’s easier to mark the rod as I described. The serious error would be to align guides off the Short Axis, and differently on each section. This would maximize vibration and stress.

In the next post I will briefly discuss rod strength and manufacturing along with a caution about how not to break your rod while casting.

Leave a Reply