3 – Fiberglass Components

Were you born after 1965? If so, your first fly rod was probably a graphite or your dad’s old fiberglass. You’ve been exposed to very little of the fiberglass world. Similar to the only foreign country you’ve seen is Mexico at Nogales during Spring break. Here I will show you the breadth of component technology used on vintage fiberglass rods. We will look at guides, ferrules, gripe and reel seats.

The top guide in the image to the right is a common snake guide. Below that is a double loop guide. These were used as stripping guides or the first one or two guides after the stripper. Of the three stripping guides pictured, the middle has an agate insert, the top a black insert, and the bottom is chrome plated. The agate insert was common on bamboo rods, and some fiberglass, but I have not seen one on graphite. Guides now benefit from high tech metals that are tougher and smoother. They have become larger in diameter, as much as two or three times the diameter of stripping guides found on old fiberglass rods.

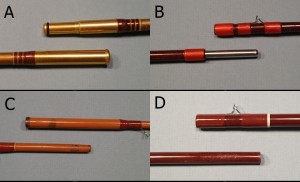

Ferrules saw significant development from those found on bamboo rods. The top-left ferrule (A) is metals, but notice the rubber o-ring often found on the more expensive rods. Metal ferrules were use exclusively on bamboo rods, and not at all on graphite. This is a butt-over-tip ferrule. The butt section fits over the tip section. The (B) ferrule is a spigot ferrule. A tapered plug is in the butt section, to the right, and the tip fits over it. A metal plug is shown here, but fiberglass and plastic were more often used. Spigot ferrules were developed by the fiberglass people and are still used today. T he (C) ferrule is a tip over butt, the female part is added to the tip blank and fits over the butt blank. Notice the metal wear and reinforcement ring. The (D) ferrule is a tip-over-butt, and is built into the rod blank. It is almost all we see on graphite rods today, and it comes with no additional labor or material cost, but when Fenwick patented the design it required two blanks to make one rod.

he (C) ferrule is a tip over butt, the female part is added to the tip blank and fits over the butt blank. Notice the metal wear and reinforcement ring. The (D) ferrule is a tip-over-butt, and is built into the rod blank. It is almost all we see on graphite rods today, and it comes with no additional labor or material cost, but when Fenwick patented the design it required two blanks to make one rod.

Fiberglass rods did not use many full-well shapes, which are most common today. The rod second from the right has a half-well grip. It tapers outward on the front. A full-well has the same taper on both ends. This rod also has a plastic sec tion on the front. The middle grip has a large metal winding check in the front and a wood and plastic piece in front of the reel seat. Grips are made of half inch sections glued together and turned to shape. Sections of wood and other materials are beginning to appear on custom grips today. As in the past, it’s about ascetics. The rod on the left is a heavy saltwater 10 weight with a fighting butt that can be inserted into the reel seat. Vintage rods have a variety of grip shapes, but cork is standard as it has always been.

tion on the front. The middle grip has a large metal winding check in the front and a wood and plastic piece in front of the reel seat. Grips are made of half inch sections glued together and turned to shape. Sections of wood and other materials are beginning to appear on custom grips today. As in the past, it’s about ascetics. The rod on the left is a heavy saltwater 10 weight with a fighting butt that can be inserted into the reel seat. Vintage rods have a variety of grip shapes, but cork is standard as it has always been.

The reel seats seen here are all down-locking. The moveable part is forced down over the reel foot. Up-locking seats were less common, but have become universal today. These were all made by threading metal tubes and attaching the fixed reel clamp to the butt end. Plastic was also used on some less expensive rods. Remember The Graduate movie, plastic was the new thing. The one feature we see new today is reel seat tube with cut outs exposing wood or synthetic inserts. Up-locking real seats are typically inset into the cork grip, which necessitates a larger diameter, rear well. What motivated the change to up-locking? I don’t know, but it does change the grip shape and move the reel weight about 1 ½ inches forward.

It is worth saying something about the thread wraps that hold the guides on the blank and provide decoration. Thread has evolved from silk to nylon, and from complex to simple wrapping. We don’t often see the multicolor wrapping today that appeared on fiberglass rods. It’s a labor cost issue. Varnish coating the wrap has become epoxy, and multiple thin coats has become one thick coat. Again, cost savings coupled with the durability of epoxy drove the changes.

The next post will start the look at specific rods starting with Conolon and Shakespeare.

[print_link]

Leave a Reply