5-Harnell

Harnell’s name is not common among the fiberglass fly rod makers, but Harnell was selling hollow tube fiberglass rods a year or two after Conolon and Shakespeare. Harnell is perhaps less known because hits founder’s interest was bass and saltwater fishing. The Harnell 1955 catalog listed 75 rod models and said that the company had sold 1,500,000 rods. There were five fly rod models selling for $25.95 each. Harnell rods are recognized by their jet black finish.

This Harnell 655 rod with its black finish has guides under-wrapped in gold and over-wrapped in red. The grip is a solid length of cork where the grain of the wood is easily visible. Every other rod in my collection has cork grips made of a series of cork rings glued together and then shaped in the same manner as they are made today. This particular rod has a non-original fighting butt added by a previous owner.

It would be interesting to know the original motivation to assemble grips from rings instead of using a solid piece of cork as Harnell did. Was it structural strength, economics, or the availability of solid lengths of cork that drove the decision? If you, the reader, have any knowledge regarding this, please comment to this post.

Harnell 655 Casting a DT 8wt line, this rod reached 87 feet without stretching the curls out of the line or working on my stroke timing. It has very small stripping guides by today’s standards, and this is common with all early fiberglass rods. They would benefit from larger guides. It is also interesting that my Pflueger 1495 reel almost didn’t fit in the seat, which needed to open slightly further. This didn’t appear to have resulted from the addition of a fighting butt. I doubt that I would reach 100 feet with the same line in my newest graphite 8wt, and that is not a lot of improvement for 50 plus years and hundreds of dollars.

[print_link]

4-Shakespeare, Conolon, & Sili-Flex

Howald and Havens started the fiberglass fly rod industry. I will start with a description of their rods in the collection, and add Sili-Flex because it was an early offshoot of Haven’s Conolon.

This first rod is a Shakespeare Wonder Rod model 1250 made in January 1953 (FHK date code). It is 8’6” rod intended for an HCH line, though the length and line size are not labeled. The down-locking reel seat and butt-over-tip metal ferrule are standard for the time. The Howald process started by placing fiberglass fibers over a balsa wood mandrel which remained in the finished rod. This rod feels a little heavy in hand and flexes at the ferrule when casting. I question the variegated thread wraps as being original, only because of the thread. In all other respects, the wraps look original.

Shakespeare Wonder Rod 1250 The second rod is a Shakespeare Wonder Rod model 1290 Presidential made in April 1960 (FAG date code). It too is an 8’6” HCH rod. The Presidential is a more expensive rod that sold for $50. The wraps are more complex, and the reel seat is up-locking spring loaded. The end would be pulled out to accept the reel, and spring tension would hold the reel in place. Up-locking was rarely used on fiberglass rods, and the spring seat didn’t catch on in the industry. Shakespeare had started using removable metal mandrels by the time this rod was made, and in this case, produced a flawless white finish. It is lighter, flexes halfway between the tip and ferrule. It is faster and performs better than the 1250 model. There is no reason not to fish this rod today, 58 years after it was made.

Shakespeare Wonder Rod Presidential 1290 Shakespeare was in the fishing business in 1905 and still is. Its first fiberglass rod was on the market in 1945 or 46. It did not spin off other manufacturers as did Conolon. In 1951 Shakespeare received a patent for fiberglass rods, and 1952 licensed the patent to 34 other manufactures for $1 each. Shakespeare allowed others to continue the development of fiberglass rod technology, and they are still in business today, while most of the 34 others are not.

Conolon was started by Glenn Havens in Costa Mesa, California at the same time as Shakespeare in Columbia, South Carolina. Conolon wrapped fiberglass fabric around a steel mandrel. This became, and still is, the standard process for fly rod manufacture. The fly rod and hollow tube industry today is largely a result of the process developed by Glenn Havens, whose rods went on the market in 1946. It is debated which company was first, Shakespeare or Conolon.

Conolon Live Fiber 6105 The Conolon Live Fiber 6105 is a 6’3” rod without a line designation. It has a standard reel seat and a high-quality butt-over-tip ferrule. Note the front of the grip has a non-cork ring, and the stripping guide is agate. I was initially surprised to find a 6-foot rod, but have since learned the many fiberglass manufactures sold a short rod. They were much more popular in the fiberglass era than today. This rod is light, tip flex, and fast action for fiberglass and casts a 6/7 weight line.

Conolon Falcon 7100 The Conolon 7100-8 Falcon rod appeared in the 1955 catalog just below their top-end rod. It is an 8” HDH (6 weight). It is the same quality as the model 6105, and it is lighter than the Shakespeare Wonder Rods and easier casting. It is a mid-tip flex rod that would be pleasant to fish today.

Sili-Flex MF85 I have included Sili-Flex in this group because it was formed in 1952 as the first spinoff from Conolon. It’s contribution to technology was curing rods in a pressurized bag. This produced a stronger and lighter wall thickness that had a smoother finish. This rod sold for $75, which reflects its quality. Note the reel seat, wraps, and Super Z ferrule. It is 8’6” 7 or 8 wt. It casts 7 well but is much better with 8wt.

Thread wrapping quality on this Sili-Flex and the Shakespeare Presidential is unsurpassed, most particularly today. It can only be found on completely custom rods if at all.

[print_link]

3 – Fiberglass Components

Were you born after 1965? If so, your first fly rod was probably a graphite or your dad’s old fiberglass. You’ve been exposed to very little of the fiberglass world. Similar to the only foreign country you’ve seen is Mexico at Nogales during Spring break. Here I will show you the breadth of component technology used on vintage fiberglass rods. We will look at guides, ferrules, gripe and reel seats.

The top guide in the image to the right is a common snake guide. Below that is a double loop guide. These were used as stripping guides or the first one or two guides after the stripper. Of the three stripping guides pictured, the middle has an agate insert, the top a black insert, and the bottom is chrome plated. The agate insert was common on bamboo rods, and some fiberglass, but I have not seen one on graphite. Guides now benefit from high tech metals that are tougher and smoother. They have become larger in diameter, as much as two or three times the diameter of stripping guides found on old fiberglass rods.

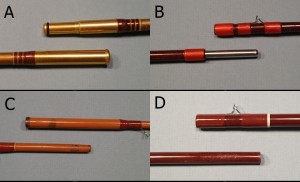

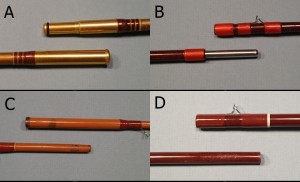

Ferrules saw significant development from those found on bamboo rods. The top-left ferrule (A) is metals, but notice the rubber o-ring often found on the more expensive rods. Metal ferrules were use exclusively on bamboo rods, and not at all on graphite. This is a butt-over-tip ferrule. The butt section fits over the tip section. The (B) ferrule is a spigot ferrule. A tapered plug is in the butt section, to the right, and the tip fits over it. A metal plug is shown here, but fiberglass and plastic were more often used. Spigot ferrules were developed by the fiberglass people and are still used today. T he (C) ferrule is a tip over butt, the female part is added to the tip blank and fits over the butt blank. Notice the metal wear and reinforcement ring. The (D) ferrule is a tip-over-butt, and is built into the rod blank. It is almost all we see on graphite rods today, and it comes with no additional labor or material cost, but when Fenwick patented the design it required two blanks to make one rod. he (C) ferrule is a tip over butt, the female part is added to the tip blank and fits over the butt blank. Notice the metal wear and reinforcement ring. The (D) ferrule is a tip-over-butt, and is built into the rod blank. It is almost all we see on graphite rods today, and it comes with no additional labor or material cost, but when Fenwick patented the design it required two blanks to make one rod.

Fiberglass rods did not use many full-well shapes, which are most common today. The rod second from the right has a half-well grip. It tapers outward on the front. A full-well has the same taper on both ends. This rod also has a plastic sec tion on the front. The middle grip has a large metal winding check in the front and a wood and plastic piece in front of the reel seat. Grips are made of half inch sections glued together and turned to shape. Sections of wood and other materials are beginning to appear on custom grips today. As in the past, it’s about ascetics. The rod on the left is a heavy saltwater 10 weight with a fighting butt that can be inserted into the reel seat. Vintage rods have a variety of grip shapes, but cork is standard as it has always been. tion on the front. The middle grip has a large metal winding check in the front and a wood and plastic piece in front of the reel seat. Grips are made of half inch sections glued together and turned to shape. Sections of wood and other materials are beginning to appear on custom grips today. As in the past, it’s about ascetics. The rod on the left is a heavy saltwater 10 weight with a fighting butt that can be inserted into the reel seat. Vintage rods have a variety of grip shapes, but cork is standard as it has always been.

The reel seats seen here are all down-locking. The moveable part is forced down over the reel foot. Up-locking seats were less common, but have become universal today. These were all made by threading metal tubes and attaching the fixed reel clamp to the butt end. Plastic was also used on some less expensive rods. Remember The Graduate movie, plastic was the new thing. The one feature we see new today is reel seat tube with cut outs exposing wood or synthetic inserts. Up-locking real seats are typically inset into the cork grip, which necessitates a larger diameter, rear well. What motivated the change to up-locking? I don’t know, but it does change the grip shape and move the reel weight about 1 ½ inches forward.

It is worth saying something about the thread wraps that hold the guides on the blank and provide decoration. Thread has evolved from silk to nylon, and from complex to simple wrapping. We don’t often see the multicolor wrapping today that appeared on fiberglass rods. It’s a labor cost issue. Varnish coating the wrap has become epoxy, and multiple thin coats has become one thick coat. Again, cost savings coupled with the durability of epoxy drove the changes.

The next post will start the look at specific rods starting with Conolon and Shakespeare.

[print_link]

2 – Fiberglass Technology

The history of fiberglass fly rods is well covered in the Victor Johnson’s book*. For this post I will focus on the technology of modern fly rods. When making your next purchase, it will help all of us to understand how a rod is made and the variables involved. Before starting down this path, I will briefly mention how it all started.

Two scientist/engineers, Dr. Havens and Dr. Howald came out of the WWII aircraft industry to develop fiberglass fly rod technology. Dr Howald developed a process of placing fiberglass fibers on a mandrel and took it to Shakespeare on the east coast. Dr. Havens started Narmco on the west coast. The Havens process wrapped fiberglass fabric around a mandrel to produce a hollow fiberglass tube. This became the industry standard process. Both companies were producing rods by 1945. People from Narmco, more than Shakespeare, soon started other companies, combining their process knowledge with the expertise of championship fly casters, and an industry was born.

How then did they build a fly rod? The process starts with a steel mandrel that is the inside diameter and taper of the of the rod. Fiberglass fabric impregnated with a binder, glue, is wrapped around the mandrel. This is wrapped with a heat shrink cellophane, and the result placed in an oven. The heat causes the binder to saturate the fabric, and the tape shrinks to compress and hold the saturated fabric in place. It is then taken from the oven to cool. The tape is removed, and the mandrel is pulled from inside leaving a tapered hollow fiberglass tube – our rod blank. Substitute graphite for fiberglass fabric and the process produces today’s graphite rod blank. In either case the blanks are sanded to remove the spiral marks left by the tape, or left un-sanded. The mandrel determines the rod taper and diameter. It can be used for three or four rods a day. Production requires many, and they must be exactly the same. These are provided by a small number of companies using a centerless grinding process. The specifications were developed by trial and error along with experienced guesses how to modify an existing mandrel to produce desired changes in rod performance. Are there algorithms today that go directly from rod characteristics to mandrel specifications? I don’t know. The first binder was phenolic, then polyester, and finally epoxy. Today the epoxy formula is one of the variables that manufacturers adjust to meet their needs. Another is the fabric material and weave. The first rods were made from square weave, an equal number of fibers in both directions, lengthwise and radial (wrapping around the rod). Radial fibers keep the rod from deforming when bent, but more fibers than necessary add weight. Fabric impregnated with a binder is called prepreg, and like mandrels is supplied by a few companies. Fabric evolved to having many more lengthwise fibers than radial. Lastly, there is the amount of material wrapped around the mandrel to produce the wall thickness.

So combine the taper, prepreg, and wall thickness with process times, temperatures, and pressures and you get the action and performance of the rod in your hand. The fiberglass people learned to understand these variables, and to manage process control in order to produce tens of thousands of identical fly rods at a reasonable cost.

In the next post I will cover the other components that go into a fine rod, and then move on to specific rods in the collection.

[print_link]

* Fiberglass Fly Rods, The Evolution Of The Modern Fly Rod From Bamboo To Graphite.

Victor R Johnson and Victor R. Johnson, Jr. , 1996 (This book is out of print and very expensive if you find a copy. However, Victor Johnson, Jr has written a 20th Anniversary Edition that provides new information. He can also provide a CD copy of the original for little cost. Contact him at www.engineeringpathways.com)

1 – Fiberglass Collection

Dad gave me a Garcia Conolin fiberglass fly rod with a old Pfluger reel in 1957. Of course it used a HCH line, and for leader I used monofiliment from my spinning reel. This didn’t change until the late 60’s, and I didn’t have a graphite rod until the early 80’s. Somewhere along the line I adv anced to tapered leaders and acquired a couple other fiberglass rods. With many graphite, “Carbon”, rods in the quiver today, I still prefer the slower actions, and I am known to over-line the fast Carbons to slow them down. anced to tapered leaders and acquired a couple other fiberglass rods. With many graphite, “Carbon”, rods in the quiver today, I still prefer the slower actions, and I am known to over-line the fast Carbons to slow them down.

Recently after 50 years of fly fishing I came upon a vintage Wright-McGill uncut fiberglass, “Glass”, rod blank, and built it into a nine weight rod to keep in the truck for carp fishing emergencies. It is a damn good rod, too good to leave in the truck, and it has proven itself casting heavy core shooting heads and landing twenty plus pound salmon. I picked up a few more W-M blanks, built a spigot ferruled five weight, and found myself reconnected to “Glass”.

Glass and I were both born in the late 40’s. By age thirty Glass had peaked and was being replaced by Carbon. It was the prominent Glass makers like Fenwick that were introducing carbon rods, and for good reason – they had developed all the technology. By the late 70’s the performance per dollar calculus gave Carbon an advantage over Glass just as it had Glass over bamboo in the late 40’s. But, Glass is still around, and gaining in popularity. Old manufactures like Orvis and Fenwick have reintroduced Glass to their product lines, and a respectable number of custom rod makers are producing glass rods made from modern blanks. We hear fly fishers say, “I like the slower delicate action of fiberglass and it durability compared to today’s fast graphite.” For many, myself included, Glass and Carbon both have their place in the quiver, and I choose to fish one or the other to enhance the day’s experience.

Having this experience and history in mind, I am setting out to build a noteworthy collection of glass rods. My goal is to represent the evolution and history of Glass. I am planning less than two dozen rods representing the evolving fiberglass technology and examples of the upper end products of the predominate manufacturers. I will stick with the vintage rods that are fishable. I don’t want a rod too good to fish, and for the purpose of the collection, I will avoid contemporary Glass.

Fly rods are a true American story. From the development of split cane in the mid 1800s to today’s carbon rods, it all happened right here in the US. Fiberglass was right in the middle. Wrapping glue impregnated fiberglass fabric over a mandrel, epoxy development, spigot and tip-over-butt ferrules, and designed hollow tube tapers are Glass technologies. Modern Carbon rods rose from improvements in material technology allowing rods to be stiffer (“faster”), lighter, and less durable because of thinner wall thickness. But, today’s high tech graphite rod makers stand on the shoulders of the fiberglass rod developers who came before them.

Finally, I will build the best glass rod that today’s technology will allow, starting with a CTS blank from New Zealand. There are other great blanks available, but my research lead to CTS. Will it out perform the best of the vintage glass rods? Follow along as I build the collection and the new rod.

[print_link]

|

|